Microseismic evaluation

From Wikimarcellus

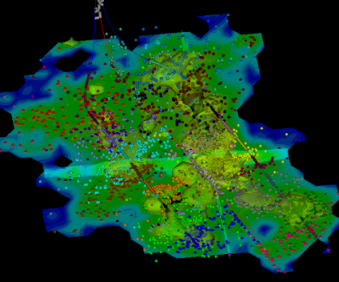

Photo courtesy of Energy Corp. of America

Microseismic evaluation consists of logging and analyzing the small seismic waves that are produced by fracturing (fraccing) a gas well. It is a versatile and accurate method of measuring the size and orientation of fractures created as a result of a hydraulic fracture stimulation.

Unlike traditional 3D seismic technologies which require an energy source, microseismic monitoring is a passive method, meaning that it listens for seismic energy which occurs underground as a result of the hydraulic fracture. Passive methods provide a continuous 4D record of seismicity in the monitoring region, rather than individual snapshots in time obtained by conventional 3D seismic methods.

Microseismic science has its roots in earthquake seismology and focuses on micro-earthquakes (i.e. with a magnitude less than zero). When rock (i.e. shale) fractures, energy is released and travels through the ground as a wave. These micro-earthquakes are too small to be felt on the surface, but they can be detected by sensors such as geophones when placed in an adjacent observation well near to the fracture treatment. As the microseismic waves travel through the earth, they lose energy and are more difficult to detect. Therefore it is advantageous to place geophones as close to the treatment zone as possible for accurate results.

Basic microseismic monitoring can map out the location where microseismic events occurred, when they occurred and how big they were (i.e. the magnitude). When microseismicity is mapped over time, operators may start to see patterns of seismicity related to production activities. Advanced microseismic analysis can begin to provide operators with additional information such as the type of rock failure that occurred and can give an indication of the total stimulated reservoir volume achieved. When compared with engineering information such as treating pressure profiles, microseismic analysis can paint a more complete picture of what his happening downhole during a hydraulic fracture treatment.

Arrays of tiltmeters, either positioned on surface or down a welbore, can also be used to study the progress of a fracture, however geophones are the preferred method for microseismic evaluation.

Photo courtesy of ESG Solutions